|

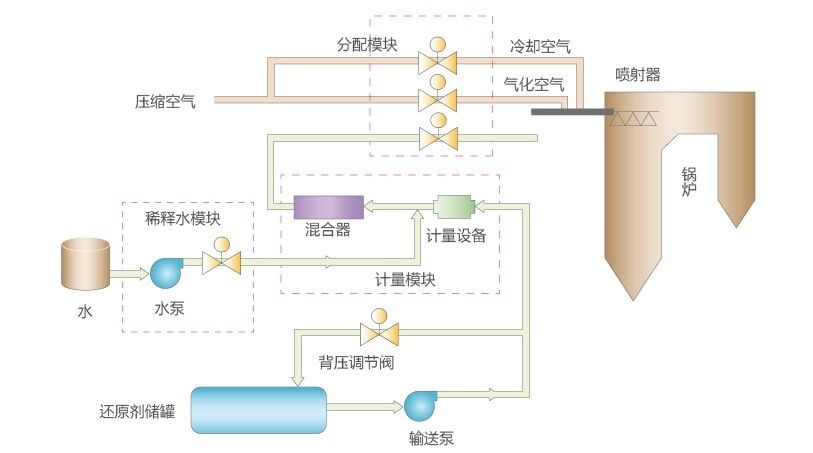

SNCR flue gas denitration

technology is the reducing agent such as ammonia, ammonia, urea solution is

sprayed into a furnace, heated to 850 ~ 1100 ℃, small temperature range, so

that NH3 or urea amino reducer can be selectively reducing NOx in flue gas,

ammonia escape 8 mg/m3, or less amount of ammonia utilization rate is higher,

and corrosive small, less side effects, treatment effect is good.

SNCR has its advantages

in small coal burning, fuel oil, waste incineration, gas unit or industrial

boiler. The SNCR system can function in a flexible manner, based on unit

operation status. It is not affected by changes of fuel or the unit's load.

Also, the process cycle is short. SNCR runs on other systems (such as air

preheater and dust collector) and does not produce interference and increase

resistance. Compared with SCR flue gas denitration technology, the investment

and operation cost of SNCR is relatively low, and there is no additional SO2/SO3

conversion rate, which is very suitable for the denitration modification of the

old factory.

|